Design

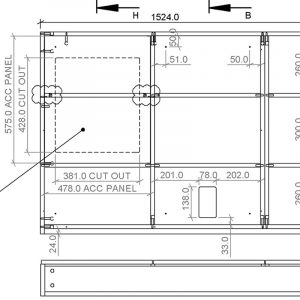

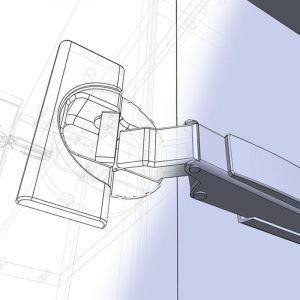

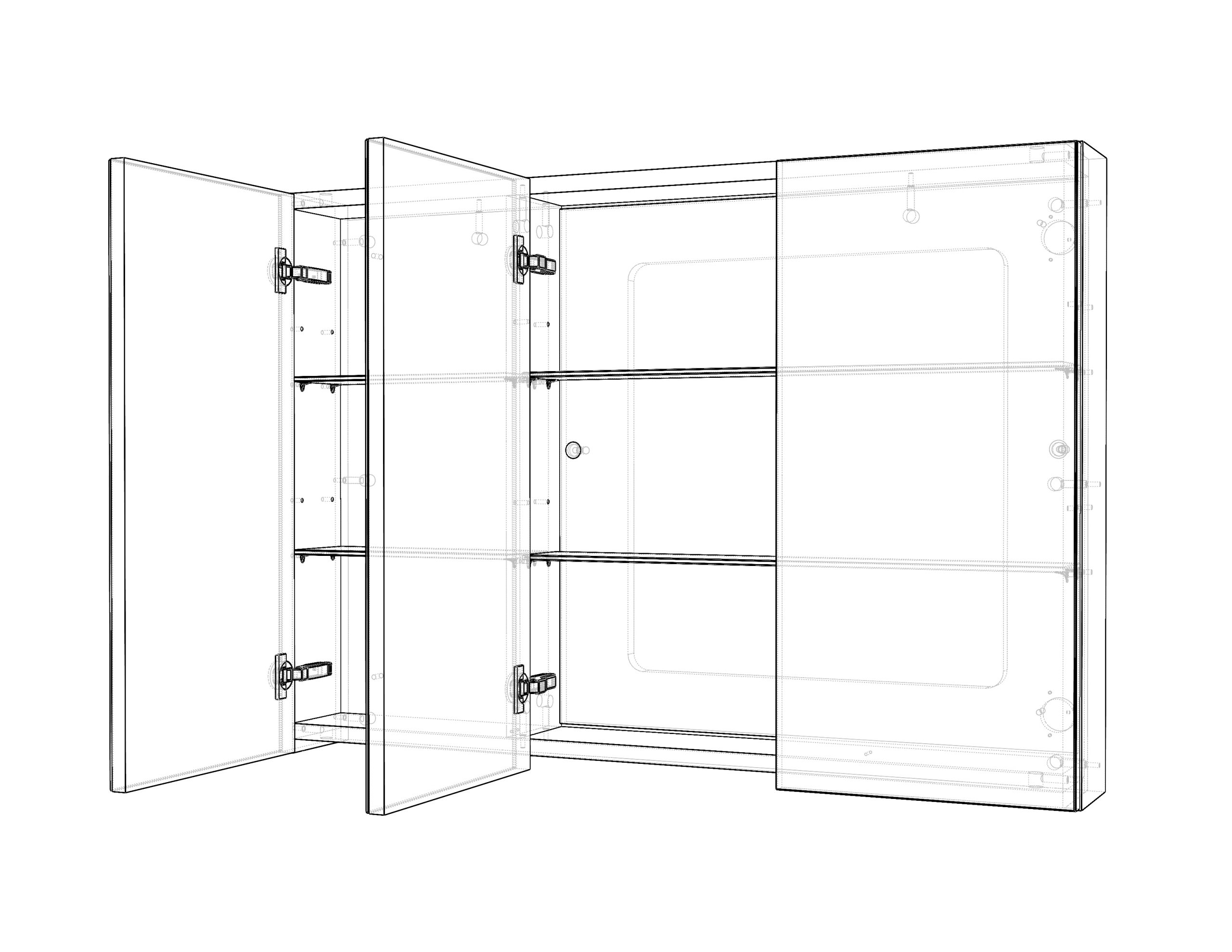

Working from the initial brief from the client, architect, interior designer and main contractor AEB will translate concepts and designs in to real life products. Ensuring the requirements and expectations of all parties are met and acting as the conduit between initial design to final product within budget. Using the latest design software being SolidWorks AEB undertake in house all technical drawings for manufacture as well as the ability to supply photo realistic renders for clients.